Gura Corporation

This article is a work-in-progress because it is incomplete and pending further input from an author. Note: The contents of this article are not considered canonical and may be inaccurate. Please comment on this article's talk page to share your input, comments and questions. |

| |

| Company type | Subsidiary of Silver Lineworks |

|---|---|

| Industry | |

| Founded | 1976; 52 years ago |

| Founder | Paulo Gurá |

| Headquarters | , |

Key people |

|

| Revenue | $35 billion |

Number of employees | 8,000 |

| Parent | Silver Lineworks |

| Divisions |

|

The Gura Corporation, stylized as GURACORP®, and commonly known as just GURA, is a Caphirian-based global advanced robotics and engineering company. Founded in 1976 by world-renowned robotics engineer Paulo Gura, the company develops robotic systems and applications in the industrial, agriculture, transportation, defense, and medical industries. Since 2018, it has been a subsidiary of Silver Lineworks - itself a subsidiary of Quicksilver Industries under its 'QS Innovations' division.

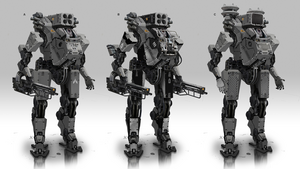

GURA is known for designing, engineering, and manufacturing tactical robot systems for law enforcement and military personnel under its MPDU product line (Multi-Purpose Deployment Unit), as well as products and services for task automation in the industrial processing of metallic and non-metallic materials for various industries including automotive, energy, aerospace, rail vehicles, and agricultural machinery. The company also develops a line of dynamic highly-mobile robots used in various applications. Over 5,000 of the company's robot systems have been deployed or are under contract.

Today, the Gura Corporation is the largest subsidiary of Silver Lineworks with over 8,000 employees across four divisions - GURA-HARDWARE®, GURA-SOFTWARE®, GURA-TECH®, and GURA-LABS®. Each division works under a "separate but together" philosophy - operating semi-autonomosly under its own management and focusing on specific areas of the business, but working closely with the other divisions to ensure overall alignment and cohesion. Since 2018, Olfražetro Andonapaci - who has been working at GURA since 1990 and was the company's first CFO, has been the Chief Executive. Founder Paulo Gura is still serving as Chief Technology Officer and Chairman, but devotes most of his time to his own autonomous research laboratory called Gura Advanced Design Solutions (GADS).

History

1976-2000

The company was founded on March 22, 1976, by Pauló Mesik Gurá. Inspired by the ability of animals to move with agility, dexterity, perception, and intelligence, Gurá set out to design and produce intricate animatronics for commercial use. After only 3 years, however, the company's burn rate was over $110,000 a month. With about 18 months of cash remaining, the company pivoted to producing low-cost domestic and municipal lighting and household appliances. By 1985, the company had doubled its workforce and made innovations in developing spot welding equipment and laser-roof-seam welding systems. These welding systems were then further expanded to adhesive bonding and sealing technologies the following year. In 1990, the company began creating robotic toys, such as a robotic eagle and a programmable Kikpari. These toys proved to be a massive financial success, and it allowed the company to hire Olfražetro Andonapaci as its CFO. Andonapaci was integral in landing the company its series A funding, raising $175 million in 1993.

In 1995, the company released its first automated product - BRACHI. The original BRACHI (BRACHI I) was a 4-axis robotic arm designed to achieve human-like dexterity and work safely around people. It has a wide range of motion, backdrivable actuators, and a hand that can grasp almost anything. Today, the BRACHI VIII system is highly configurable and available in 3, 5, 7, 9, and 12-axis systems and features custom high-performance servo-electronics that are the lightest in the world - at 35 grams. The BRACHI system has utilized interchangeable components since BRACHI II, making it versatile in specialized industries. Today, the company maintains exclusive licenses with many of the top medical, scientific, and industrial corporations in the world.

To meet the demand for its products, the company began to develop internal tools, software, and robotic modules that could assemble small goods, such as household appliances, tools, and electronics. The modules could be plugged together to create a small assembly line, and the robots could be programmed through the company's software to follow instructions.

2000-2012

Over the next decade, the Gura Corporation continued to grow and expand its product offerings, becoming a leader in the robotics and engineering industries. In 2002, GURA released the first iteration of its MPDU product line for law enforcement and military personnel, revolutionizing tactical operations and providing advanced robotics technology for dangerous and complex missions. In 2005, GURA developed the world's first self-driving mining truck, providing increased efficiency and safety for heavy industrial operations. In 2006, GURA's BRACHI system was used to assist with disaster relief efforts in the aftermath of the massive earthquake in Meceria. The system's dexterity and mobility made it the ideal tool for rescue and recovery operations in the unstable rubble of damaged buildings.

In 2008, GURA partnered with the Royal Moorden Hospital, one of the world's leading medical institutions to develop cutting-edge surgical robots, providing precise and minimally invasive surgeries for patients. The company's surgical robots became the gold standard in medical robotics, and over the next decade, GURA's robots were used in over a million surgeries worldwide.

In 2010, GURA created the first fully automated assembly line for the production of consumer electronics, providing increased efficiency and reducing human error in the production process. The assembly line was adopted by many leading electronics companies, most notably Petalstone Electronics, leading to significant improvements in their manufacturing processes. Petalstone attempted to outright buy the company and upon failing that, tried to settle for a majority stake. After several years of negotations, Gura accepted a small investment from Petalstone in exchange for a minority controlling interest in the company.

2012-2020

In March 2012, the company had a private valuation at $3.6 billion and underwent a signifigant restructuring proccess: all of the consumer hardware teams would merge under the GURA-HARDWARE division, as well as the company's "micro-factories" that build its products; a GURA-SOFTWARE division would be created to develop software tools to improving efficiencies in the manufacturing process, as well as maintaining its open control architecture across its hardware products and even provides source code for customers who wish to develop software for different platforms, or to modify the code for their own use cases. A third division, GURA-TECH was formed to offers standard and customized products for industrial production automation; joining technologies and component handling are amongst their activity. The technologies are tested and the production processes are fully optimized prior to the development. In addition, GURA-TECH offers engineering consultations to individuals and corporations. In 2014, GURA's BRACHI system was used in the restoration and preservation of ancient ruins and artifacts in Zaclaria, providing precise and delicate handling for sensitive historical objects.

By 2016, GURA was awarded the prestigious "Robotics Company of the Year" award for the 4th time at the International Robotics Conference for its contributions to the field of robotics and its impact on various industries. At the IRC, executives from Quicksilver Industries were present and were impressed with the cutting-edge technology and the market dominance of Gura in the tactical robotics sector. They saw the potential for significant growth and expansion through a strategic partnership with Gura, as they planned to restructure their robotics division and rebuild it with Gura at the center.

Paulo Gura, being the visionary and perfectionist that he is, was initially resistant to the idea. He was fiercely protective of his company and its legacy, and did not want to see it being absorbed by another corporation. An initial meeting was set up between the two companies to discuss potential collaboration and business opportunities. During the meeting, Silver Lineworks presented their vision for the future of robotics and how the Gura Corporation could play a significant role in shaping that future. Despite seeming interested during the meeting, Gura ultimately rejected any sort of acquisition or merger, but welcomed specific contracts.

After months of negotations, Silver Lineworks entered into a strategic partnership with the Gura Corporation, which allowed them to acquire a sizeable but minority stake in the company. The partnership was aimed at leveraging the synergies between the two companies and providing additional resources to drive growth and innovation. This partnership allowed Gura to further develop its line of dynamic highly-mobile robots, offering innovative solutions for various industries including transportation, agriculture, and defense. It also allowed the company the ability to focus on other projects.

Under the guidance of Silver Lineworks, the Gura Corporation's GURA-TECH division was able to redirect its focus to developing cutting-edge technology solutions for the Internet of Things (IoT) and Industry 4.0. The division leveraged its expertise in automation and engineering to create sophisticated automation systems that could monitor, analyze, and control industrial equipment, processes, and networks. The GURA-TECH division became known for its innovative Industry 4.0 solutions that were utilized in various industries, including manufacturing, energy, and healthcare.

On the other hand, the GURA-SOFTWARE division had the opportunity to expand its capabilities in software development, focusing on creating powerful and intuitive user interfaces for robotic systems. The division utilized its knowledge in robotics, artificial intelligence, and data analytics to design and develop software solutions that provided real-time insights and control over the performance of the company's robotic systems. Additionally, the GURA-SOFTWARE division began developing custom software solutions for various industries, including transportation, aerospace, and agriculture, to meet the demands of the modern, technology-driven world.

Acquisition by Silver Lineworks

By the end of 2019, the Gura Corporation was given the "Robotics Company of the Decade" award from the IRC and was valued at aproximately $10 billion. Silver Lineworks once more approached Gura to reasses their partnership. The company wanted to form a joint venture with Gura, aimed at expanding their operations globally and ultimately lead to a full acquisition. Much like last time, Gura was largely uncooperative in the business dealings.

After months of negotiations and five failed proposals, Silver Lineworks presented Paulo Gura with a sixth and final proposal: it would would allow him to retain creative control over the Gura Corporation while giving him access to the resources and expertise of Silver Lineworks (and by extension, Quicksilver Industries). The deal was structured as an asset purchase, with Gura Corporation becoming a subsidiary of Silver Lineworks, but with Gura staying on as the Chief Innovations Officer. The deal would also give Gura his own research laboratory called Gura Advanced Design Solutions.

Gura was intrigued by the prospect of having access to a massive pool of resources and cutting-edge technologies, but was wary of losing control over the company he had built from the ground up. In the end, he agreed to the asset purchase on the condition that the Gura Corporation would maintain its operational autonomy within the Silver Lineworks umbrella and that GADS would be given full autonomy to pursue its research without any interference from Silver Lineworks. Gura's agreement to the asset purchase came as a surprise to many, as he was known for being fiercely independent and protective of his company. But the prospect of having the resources and expertise of Silver Lineworks at his disposal was too enticing to pass up, and he saw it as an opportunity to take the Gura Corporation to the next level. The deal was finalized in mid-2018 and the purchase completed in 2019.

Today, the Gura Corporation is the largest subsidiary of Silver Lineworks, with over 5,000 employees across four divisions. Under Gura's leadership, Gura Corporation continued to innovate and push the boundaries of robotics and engineering, solidifying its position as a leader in the industry.

2020-present

Corporate structure

Executive management

Paulo Gurá, who founded the company in 1976 and remains a key figure in the company's success, currently holds the title of Chief Technology Officer and Chairman, and is responsible for setting the company's technical direction and overseeing the research and development of its products. Under his leadership, Gura has grown into a leading robotics and engineering company, with a strong presence in the industrial, agriculture, transportation, defense, and medical industries.

The current Chief Executive of the Gura Corporation is Olfražetro Andonapaci, who also served as CFO from 1990 to 2020. Andonapaci is credited with securing the company's Series A funding in 1993, which helped the company expand into new markets and develop innovative products. Today, he is responsible for the company's financial strategy and ensuring that the company has the resources it needs to achieve its goals. The Vice Executive is Bashah Al-Omardou, who has extensive experience in the field of software engineering and artificial intelligence. Each division is led by an executive engineer, an industry veteran with decades of experience.

- Paulo Gurá, Chairman of the Board & CTO

- Olfražetro Andonapaci, Chief Executive

- Bashah Al-Omardou, Vice Executive

- Marko Ciković, Executive Engineer of GURA-HARDWARE

- Dr. Enrico Molnár, Executive Engineer of GURA-SOFTWARE

- Kostya Petrov, Executive Engineer of GURA-TECH

- Dr. Ava Delgado, Executive Engineer of GURA-LABS

Organization

The Gura Corporation operates under a highly structured corporate model, with four distinct divisions - GURA-HARDWARE®, GURA-SOFTWARE®, GURA-TECH®, and GURA-LABS®. Each division operates semi-autonomously with its own management and focuses on specific areas of the business, but works closely with the other divisions to ensure alignment and synergy throughout the company.

GURA-HARDWARE

GURA-HARDWARE is the division is responsible for the design, engineering, and manufacturing of advanced robotic systems. The division also creates hardware for various industries including industrial processing, transportation, and military. It is led by seasoned engineer Marko Ciković, who has been with the Gura Corporation for over 20 years.

The division is best known for the Situational Reconnaissance Unit - a highly mobile tactical robot system used by military and law enforcement personnel, and the BRACHI series, a line of highly configurable robotic arms used in various industries including medical, scientific, and industrial production.

Outside of its robotic systems, other notable projects that have come out of GURA-HARDWARE include the GuraDRIVE™, an advanced motor and drive system for use in harsh industrial environments, and the GuraSENS™, a range of industrial sensors designed to withstand tough conditions and provide reliable data. In addition, the division has also developed a line of robotic exosuits, called the GuraSUIT™, which allow users to work in hazardous or inaccessible environments with enhanced strength and dexterity. GURA-HARDWARE has also been involved in the development of cutting-edge robotic systems for the automotive industry, energy-efficient home lighting systems, and aerospace-grade materials for high-altitude applications.

In addition to its hardware products, GURA-HARDWARE also provides support services such as training, maintenance, and technical assistance to its customers. The division's focus on customer satisfaction has earned it numerous accolades, including the "Top Provider of Robotic Hardware Solutions" award from the Robotics Industry Association for 5 consecutive years. The division has invested heavily in R&D and is constantly exploring new materials and technologies to further enhance its products. This focus on innovation has made GURA-HARDWARE a key player in the industry, with many of its products being recognized for their superior quality and performance.

GURA-SOFTWARE

GURA-SOFTWARE is responsible for developing the software and programming tools that support the hardware produced by GURA-HARDWARE. It was created to improve the efficiency and accuracy of the manufacturing process, as well as to provide a seamless open control architecture across all hardware products, enabling customers to modify the code for their own use cases. Leading GURA-SOFTWARE is Dr. Enrico Molnár, who has over 15 years of experience in the software engineering industry. The software engineers work closely with the hardware engineers in GURA-HARDWARE to ensure a seamless product.

GURA-SOFTWARE produces many software solutions for the industrial, defense, and healthcare industries. Some of its most popular products and services are packaged together under its G-Suite service.

The most popular application in G-Suite is GURANET, the company's proprietary software platform that enables real-time monitoring and control of robots and automated systems. It provides real-time data analytics, remote diagnosis, and real-time optimization of manufacturing processes, as well as allows for remote maintenance and updates. GURANET connects multiple robots across a single network, providing users with improved performance and reliability, and centralized control over their robots. The platform integrates seamlessly with existing production management systems and can be configured to support multiple languages and regions.

Another common G-Suite application is Control Center, a highly-advanced and user-friendly interface that gives users control over their robot systems. It features a simple, drag-and-drop interface, making it easy for non-technical users to program and control their robots. The platform is designed to be scalable, supporting thousands of robots simultaneously.

GURA-SOFTWARE also offers cutting-edge machine vision systems that use advanced computer algorithms and sensors to help robots "see" the world. This technology allows robots to inspect, sort, and identify objects and products with incredible accuracy, making it an essential tool for industries like automotive and healthcare. Another popular application is the GURA-FLEX Assembly System, a modular and scalable solution for automating the assembly of small goods, such as household appliances, tools, and electronics. The system features intuitive programming software and a wide range of interchangeable robotic modules, which can be easily configured to fit specific manufacturing needs. Another application is the GURA-DRIVE Intelligent Motion Control System, is a sophisticated software platform that provides advanced motion control capabilities for robots. The system is capable of optimizing robotic movements to achieve maximum speed, accuracy, and stability, while also providing advanced safety features to prevent damage to machinery or products.

In addition, the division is also responsible for maintaining the open control architecture of the company's hardware products, which allows for greater flexibility and customization. The company's open source code policy has been well received by the industry, and has helped to establish the company as a leader in the field of robotics and automation.

GURA-TECH

GURA-TECH is responsible for offering standard and customized products for industrial production automation. This division is dedicated to providing innovative and efficient technologies and solutions to enhance the manufacturing process. The team at GURA-TECH, lead by veteran engineer, Kostya Petrov, is constantly working to create new solutions to improve the efficiency and productivity of industrial operations.

One of the core services of GURA-TECH is engineering consultations, which provides valuable expertise and support to individuals and corporations looking to optimize their production processes. This includes the optimization of existing technologies, the integration of new technologies, and the development of new solutions for specific applications. The division is also responsible for the development and testing of technologies that are used in the production of other Gura products. This includes technologies related to joining and component handling.

Some of the notable projects that have come from GURA-TECH include the development of a highly efficient and cost-effective system for the automation of small components in the automotive industry. This system has been widely adopted by several major automobile manufacturers and has been praised for its ease of use and reliability. Another project that has received significant recognition is the development of a cutting-edge welding technology that has revolutionized the way metal components are joined. This technology has been widely adopted by aerospace and shipbuilding industries and has received several awards for its innovation.

GURA-TECH offers a range of standard and customized products for industrial production automation, including the design, engineering, and installation of automated assembly line systems, the design and installation of custom robotic systems for specific applications, and more. For example, GURA-TECH worked with the Thessia Aerospace Corporation to design and install a custom robotic system for their manufacturing facility. The system has improved the production efficiency by 50% and has also reduced the need for manual labor.

GURA-LABS

GURA-LABS is the cutting-edge research and development division of The Gura Corporation. It is responsible for the design, creation, and implementation of innovative technological solutions in the robotics and engineering industries. GURA-LABS is led by world-renowned artificial intelligence researcher, Dr. Ava Delgado. GURA-LABS is known for its ground-breaking research in artificial intelligence, computational neuroscience, and biotechnology. This includes the development of advanced robotic systems, such as autonomous vehicles, mobile robots, and advanced prosthetics, as well as the creation of new software and hardware systems for robotics and automation.

Some of the most notable projects that have come out of GURA-LABS include the development of a highly-efficient autonomous drone system for use in agriculture and mining, as well as a line of advanced prosthetics that integrate cutting-edge robotics and biotechnology to help individuals with disabilities regain mobility. The division also has ongoing research into developing new materials and manufacturing techniques that can help reduce the environmental impact of industrial production.

Other active projects include a range of robotic systems that can assist in disaster relief efforts. From search-and-rescue robots to drones that can deliver supplies and medical aid, these systems are being designed to help save lives and reduce the impact of natural disasters. GURA-LABS is exploring the use of artificial intelligence in healthcare, with a focus on developing systems that can assist in the diagnosis and treatment of diseases. The goal is to create systems that can help healthcare professionals make more accurate diagnoses, provide more personalized treatments, and reduce the burden on healthcare systems. GURA-LABS is also working on a range of robotic systems designed for use in space exploration. These systems will be able to perform tasks such as collecting data, exploring new environments, and performing maintenance on satellites and other space-based infrastructure.

Products

BRACHI

MPDU

God's Hand